Rust on metal buildings begins as a speck. However, if unchecked, creeping rust begins to spread across the surface. Structural integrity is compromised by corrosion, which also shortens the current lifespan of the metal structure and diminishes its monetary value.

“Man of Steel” and steel-framed structures

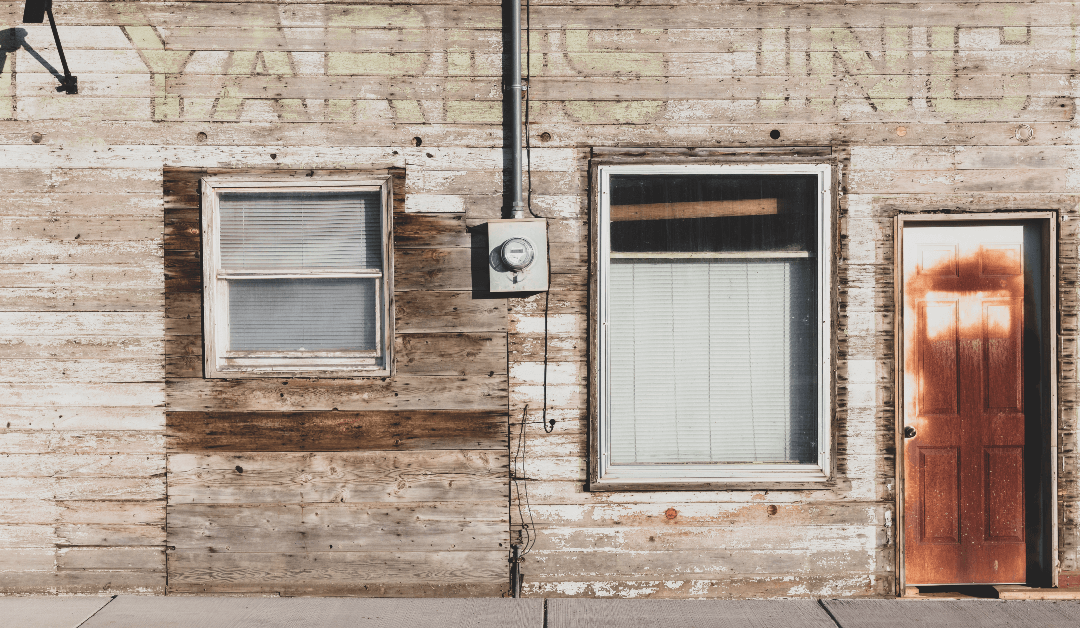

The prevention of rust on metal buildings is depicted in rusty letters. Steel has always been linked with remarkable sturdiness and durability. As a result, “Man of Steel” is another nickname for Superman. Steel, the hero of construction materials, has one fatal flaw: its tendency to rust.

Steel can withstand ferocious storms, screaming winds, and even time itself. Wooden constructions are vulnerable to fire, mold, and termites, all of which they bravely battle. Rust, however, creeps at every corner, hoping to find a way to defy steel as Lex Luther waits in the shadows.

The dangers of rust on metal buildings

Rust can produce significant issues like these if left unchecked:

- Crusty patches that detract from the structure’s appearance and value

- Wet insulation and dampened building contents are the results of leaks.

- Mold and hazardous tetanus spores are just some of the health issues.

- Deteriorated structural stability.

Purchase a high-quality structure with rust-resistant features to avoid corrosion on metal buildings.

How to stop rust on metal

- RHINO only offers rust proof screws

The cast zinc heads on the aluminum self-drilling screws are guaranteed against red-rust corrosion for the life of your screwdriver. Additionally, each screw includes an EPDM synthetic rubber washer of the highest quality. It is also worth noting that EPDM washers provide additional ozone and ultraviolet degradation protection.

- Better base

All of RHINO’s orders come with formed-base trim, which the company uses to keep metal structures free of rust. This trim extends the steel panel slightly beyond the foundation edge. The steel panels sit in a small dip generated at the base of cheaply made metal buildings.

The water seeps into the steel paneling at the border of the hole. Rusted steel panels are a possible result of corrosion. Therefore, the steel panel is never submerged in water, and water does not flow onto the foundation.

- Better coatings

Steel panels not coated with a protective coating corrode quickly. Nevertheless, RHINO does not make use of steel panels of low quality. For added protection, our 26-gauge PBR panels have more overlap.

All of RHINO’s keyframing components are coated in rust-resistant paint as an additional layer of protection. This red-oxide paint, which is applied throughout the manufacturing process, protects the steel from rust.

- Opening Trim

Steel building openings with red-iron jambs and headers exposed to the weather have no opening trim. The steel framing is protected, and at the same time, the opening trim adds aesthetic appeal. All RHINO kits come with the same trim at no extra charge, unlike many other metal building companies.